This posting is only my report of the trip. Talk to the others for their thoughts. I have included a few images here (some are mine, others are from Rick, Karen, Andrea or Ron) but there are lots and lots more. A photo gallery of some of the best pictures is also being posted. Great fun!! Cheers, Mark

Wander lust! (/wän ● der ● lust/ noun: wanderlust – A deep uncontrollable desire to hit the road and travel, by whatever means desired, to explore and enjoy the world – according to the omniscient internet.)

And when you have a Morgan, the Morgan morphs into the ‘whatever means desired’.

It seems that every so often, I just have to go. Perhaps, it’s hereditary or instinctual or just innate. I don’t know, but the juices start to flow and the voices in my head speak to me (yes! I too hear voices, or am I just talking to myself?). I can’t sleep, don’t eat well, drink too much.

Ok, so tell me you too know the feelings?

Well, I was cutting the grass one morning, early to beat the rain. We do most things early in Florida to beat the rain, or the heat or the humidity. There I was and it came to me. “Take the train or your butt will hurt.”

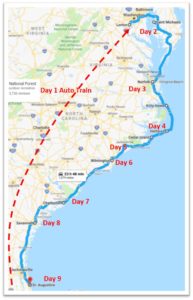

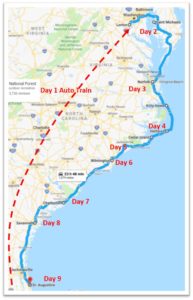

So here we are. GatorMOG’s Mid-Atlantic Road Trip. We load the Morgans and go North to Washington D.C. on Amtrak’s Auto Train and then drive ‘unhurriedly’ back down the Mid-Atlantic coast. Nothing too fast, nothing too far. Good hotels, good food and just enough company to mix up the daily routine. Well, that was the plan anyway.

This ‘Road Trip’ is a bit different than the others we have been on and we planned it that way on purpose. This road trip’s philosophy is three-fold. (1) Limit driving time. No marathon drives. We are getting older and unfolding is hard. (2) No drive-by visits. Too many times we have been to a town or a location and haven’t had the time to see any of the sites. We arrive, after driving all day, eat dinner, sleep in some non-descript hotel and then leave the next morning. And, finally, (3) Limit the number of participants. Too many folks necessitate group rates at hotels, restaurants that can handle large crowds, support vehicles, etc. Too much work to plan and organize. Herding cats is hard!

Now, taking your car on the train is really a thing of the past. The only operating auto train in the US is the one that travels between Sanford, Florida (where I now live) and Lorton, Virginia (where I used to live, how weird is that?) Lorton, Virginia is just a car wreck south of Washington DC, off I-95; so, for this trip, it is where we needed to go.

The opportunities for taking your car on the train are dwindling in Europe as well. There used to be many choices but now just a few. Sad. Anyway, this is not the first time down the tracks for the others and I, nor the Morgans.

Day 0 of this Road Trip was preparation day. 8 October 2018.

This was a GatorMOG event and we had folks from both sides of the Florida Peninsula going on this trip.

So, to avoid any last minute trauma, we had the West Coast folks, Ron and Kathy Gricius, travel to Sanford (on the eastern side of the peninsula) on Monday morning, to Mark and Andrea’s abode.

This left us time to put Ron’s car on the lift, tighten those things that needed tightening and to react to anything else that needed reacting. Well, it was all good, with no trauma, no reacting. So, we just played. Best to plan for the gremlins and have the time to fight them off, rather than to not plan for them and need to do battle, or worse yet, fall on your sword, at the last moment!

| Photo Courtesy of Rick Frazee |

Day 1 of this Road Trip was all about the train. 9 October 2018. We headed to the Amtrak station mid-morning. You need to go ‘check-in’ to verify your tickets are still correct and to sign up for your preferred dinner ‘sitting’. They have different dinner ‘sittings’, sort of like a cruise ship. If you want dinner prior to 9 PM you had better get there early and make your dining preference known. There were eight of us going north on the train. Rick and Sam Frazee in their BRG Roadster, John and Debbie Stanley in ‘Ruby’, their ruby red 2005 Roadster, Ron and Kathy Gricius in their 2003, Ferrari Red, Anniversary Plus 8, and yours truly in the two-toned, BRG over Cream ‘05 Roadster. Once everyone accomplished all the requisite admin, we headed to downtown Sanford for lunch. We found a meal at a Brew Pub. Sanford is sprouting these things left and right. There are five now. For a town born on Celery, beer is now king. Go figure?

We loaded our Morgans on the train in the afternoon. Actually, Amtrak provides the drivers to load the cars, and it is a good thing, as they know the deal, narrow wheel tracks in narrow train cars. Just the thought of navigating those constraints gives me the willies! But, they are a bit challenged with the Morgans. Not all the Amtrak drivers are skilled (or old enough) to drive a manual transmission. They soon figure out the problem and then they call for ‘Lewie.’ They put the Morgans on last, driving them into the lower deck, so that they didn’t have to negotiate the steeper angles of the loading ramps. This was good. We did put a few extra pounds of pressure into the tires to assure maximum clearance, but it probably wasn’t needed.

Once the cars were loaded, we personally got to board the train, find our cabins, and then we headed to the ‘bar’ car. Not much there. But, the ‘bar’ car was our evening entertainment. Expensive (but not fancy) wine, free cheese and crackers with each wine purchase, and pent up energy anticipating the adventure ahead. We all went back to the ‘rooms’ to freshen up before dinner. As said in a recent country song, I can only get so ‘fancy’.

Eventually, they called us to the dining car and down the aisle we went. Dinner was surprisingly good, and they turned down our beds while we were out in the dining car. After dinner, a little evening repose and finally we drifted off to the gentle rocking (with a few jolts?) of the train. The only challenge is the bunk beds and getting down the ladder at night to the bathroom.

Again, in the morning, they called us to the dining car for breakfast. Again, we stumbled down the aisle to the dining car. Breakfast is only served to those that are interested and soon we arrived in Lorton. It’s about 8:30 AM. We are early. The cars get off-loaded and we configure the Morgans for Day 2’s excitement. And yes, our butts didn’t hurt!!

Configuring the Morgans is certainly Task 1. We had the roof (hood) up for the train ride, too many birds in the train cars, but wanted to put the hoods down for the drive across the bay. It’s warm in Virginia so the tops come off. We also had to re-stow our bags from overnight. Utilizing the Morgan’s space efficiently is no easy task. A bit like that chicklets game, sliding this to the left and that to the right, somethings up and somethings back. We didn’t take much onto the train as the sleeping berth stairways are very narrow. But, we did have ‘things’, and those ‘things’ needed to be re-stowed so that we could get the hood down and weren’t jettisoning underwear, as we went down the road.

Day 2 of this Road Trip, 10 October 2018, was a sprint from Lorton, VA to St Michaels on the Eastern Shore of Maryland and it involved us taking the southeastern side of the I-495 D.C. Beltway. It’s the only way to get to St Michaels, going over the Chesapeake Bay Bridge. Well, I guess we could swim . . .

Well, we did it. Minimal drama. Lots of new roads and morning traffic, but Morgans traveling in groups is a good thing . . . I think. Makes us more visible to the ‘not quite awake’ folks suffering (sleeping?) through this same commute – day after day after day – more focused on the ‘day ahead’ than the rest of the world or too busy texting.

Well, we did it. Minimal drama. Lots of new roads and morning traffic, but Morgans traveling in groups is a good thing . . . I think. Makes us more visible to the ‘not quite awake’ folks suffering (sleeping?) through this same commute – day after day after day – more focused on the ‘day ahead’ than the rest of the world or too busy texting.

St Michaels is a great maritime town along the water on Maryland’s eastern shore. It was here we met up with another couple in our traveling band. Karen and Chuck Bernath have family on the Eastern Shore, so they traveled up earlier in their Plus 8.

The afternoon was spent visiting the maritime museum, historical boat tours, shopping, or in my case, napping. I had been to the museum before and I was exhausted. We stayed in a B&B in the heart of St Michaels. Lovely location and nice hotel.

We did have some sprinkles during the night. It seemed to be light and intermittent. And then the crabs came out. Something about St Michaels and the eastern shore of Maryland. Crabs everywhere!

Day 3 of this Road Trip, 11 October 2018, had us traveling from St Michaels MD to Virginia Beach, VA. We left St Michaels on what seemed like a British summer day. Hot, humid and spitting rain. Tops up and claustrophobic. The only real use of the windscreen wipers.

| Photo Courtesy of Rick Frazee |

We traveled south to lunch in Cape Charles. After lunch, the tops came down as the sun came out. Then we ventured over the Chesapeake Bay Tunnel-Bridge complex, into the Norfolk, Virginia Beach area. The plan was to hug the Atlantic Coast and go to Military Aviation Museum and an ocean side restaurant for dinner. However, in the interest of safety, we opted do go directly to our hotel and stay there for dinner. Hurricane Michael was coming!

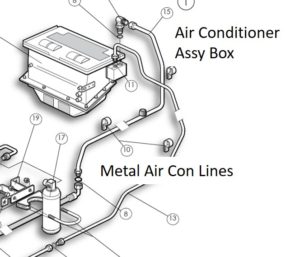

I had developed a mechanical problem with my car. It turned out that a hose clamp that was situated ‘just so’, was rubbing a pinhole in another rubber coolant hose. When the car got really hot the pinhole steamed like a freight train and allowed coolant to escape the system. This steam loss obviously resulted in a reduced level of engine coolant, making the car even hotter. A vicious cycle, so I had been putting in coolant (or water) as a quick fix but this resulted in a few too many unplanned stops. We arrived in VA Beach a little later than planned.

Since old friends of ours from MCCDC, Richard Lipski and Peggy Morris were joining us for dinner, I called Richard and asked him to bring us a few auto parts. I needed a length of radiator hose and a few hose clamps. We had a great visit with Richard and Peggy at the hotel and then we all went our separate ways to find our rooms. We were pretty tired and had a big day facing us. The plan was to rewicker the schedule and, in the morning, go to the Aviation Museum we had previously skipped due to the forecasted Hurricane.

The Hurricane came through Virginia Beach while we were all asleep. We woke up to a dark hotel, without power. Luckily the backup power was just sufficient enough for breakfast and to power the elevators. (I am getting too old to drag the luggage up and down the stairs!)

Day 4 of this Road Trip, 12 October 2018, was smooth sailing now that the hurricane had passed us by. We altered the plan slightly to see old airplanes and called an audible for lunch. We waved at the Wright Brothers Monument as we drove by. No time to stop and fly the kites we had brought. Oh well, we just needed to get from Virginia Beach, VA to Hatteras, NC.

After the hotel cooked us breakfast and the sun came up, we headed out to the parking lot. Thanks to Rick, Ron, and the parts Richard Lipski brought us (we still needed a trip to the local hardware and auto parts store) we fixed my coolant hose problem and headed for the Aviation Museum.

The Aviation Museum was certainly worth the schedule deviation. It was extensive and focused on significant WWI and WWII military fighter planes. (Along, with other related exhibits.) Amazing stuff and stuff I really enjoy. Certainly, for me it was a great place to visit and spend a few hours.

We hurried along best we could, listening to the docents and taking in all the amazing aircraft. We did leave just a few minutes before the tour was over. We had to get down the road to lunch.

We found a nearby spot for lunch and then continued on our way to Hatteras, NC. I was pleased that my car was running well and cool, and now gasoline powered and not steam powered.

We skipped the planned stop at Kitty Hawk, as the visitor’s center was closed (a two-year renovation, they said?).

We passed a good bit of debris on the curbs as we traveled south along the coast road (NC-12). Most of this was due to Hurricane Florence. My heart goes out to those dealing with all this mess.

The drive after lunch was spectacular with the dunes and marsh grass of the North Carolina outer banks. We hugged the coast going south. Good roads with minimal traffic. Some of which was National Park, the Cape Hatteras National Seashore.

We did have a few ‘nautical’ events along the way. We had to cross a number of places where the road had flooded from over-wash from the Atlantic Ocean, remnants of the recent Hurricane Michael. To me, it wasn’t too deep to drive through and I just followed the vehicles ahead of me. In some cases, I stayed to the dry (high) side of the road. It was sort of like the old historic Morgan photos with the cars driving through the water during field trials or some such.

Others on the trip didn’t see it as I did and swore it was very, very deep. So much so they needed ‘snorkles’! I’m still not so sure about that, but I was at the front of the pack and didn’t experience the ‘sloshing’ waves those in the rear surely had. I suspect the water we crossed will get deeper and deeper as time goes by.

Certainly, good stories for the noggins to come!

Getting to Hatteras, NC was paramount, so we pushed on and washed the Atlantic Ocean from the cars once we stopped. The hotel had a convenient hose and they allowed us to use it. Our abode for the night was a fishing hotel on the coast. Quaint but a bit musty. The restaurant however wasn’t too bad.

Day 5 of this Road Trip, 13 October 2018, was spent on the Ferries. Two Ferries actually, the first from Hatteras, NC to Ocracoke, NC and the second from Ocracoke, NC to Cedar Island, NC. The Ferry operation was quite punctual, and we got in line early to assure we didn’t miss the boat. Actually, we were there too early and caught an earlier ferry. This gave us time to stop to see the wild ponies of Ocracoke. They ran free on the island until their safety was challenged by increasing traffic and they were corralled in the 1950s. And that’s where they were when we stopped. Way away from the traffic, safely corralled and way beyond our sight. Maybe it was breakfast time?

After a short while we got back in the cars and headed to the lunch stop. We ate in Ocracoke and then got in line for the 2nd ferry.

Riding the two ferries took us all day. But, all in all, it was great fun. Ron Gricius had these plastic car covers and tried to use one on the ferry. It became a group-grope which involved several other passengers and even some of the crew. It didn’t work as the wind fought them hard. Finally, the cover was shredded, stuffed into the car and the car’s tonneau buttoned up. We had a tremendous laugh.

Once off the second ferry we traveled down the road about an hour to our hotel in Atlantic Beach, NC. Finding operating hotels in this part of the country proved to be the toughest part of our trip. All our pre-arranged hotel reservations were cancelled, by two other hotels, due to storm damage. We had to react to mother nature and find other accommodations. In the end, everything worked out quite well.

Day 6 of this Road Trip, 14 October 2018, was spend traveling south along the North Carolina coast. Our objective was Wilmington NC. It was hot, and my supposed ‘air conditioner’ was pretty much useless. Our hotel in Wilmington, NC was just across the water from the berthed USS North Carolina, a WWII Battleship. I was looking forward to the visit but then I had to choose. A nap or a long walk to get there, and up and down the many stairways on the ship. I hate to say it, but I chose the nap. Andrea, however, ventured out and down the river walk and to a historical mansion (Bellamy Mansion) up the street from our hotel, as did a number of other folks. It turned out that nobody actually went to the ship??

The group did find an interesting pub. Lots of beer on tap and beer kegs for urinals?? The food wasn’t recommended so they all went to another pub down the street to eat.

Day 7 of the Trip, 15 October 2018, found us in Charleston, SC. We arrived a little late and, since the hotel’s restaurant was closed, lunch for some was quite light. (Crackers?) Andrea and I made a quick stop to see Charlie King’s widow, Caroline, and check on in on her. She seems to be doing ok, but Charlie’s recent passing had obviously taken its toll. Hopefully, she will join us for the Holiday Party in December.

Being the tourists we all were, we ventured into town and found a horse drawn trolley to take us around the historic district of the town. This is a great way to get quickly introduced to the magic and mystery of a new place. The trolley drivers are all really tour guides and give you quite a bit about the folk lore and history of the region. And the pace of the horses is just about perfect. Several of us ate dinner in an old church near the stables of the carriage ride. Pretty cool atmosphere.

Day 8, 16 October 2018, found us circling the squares in Savanah GA. We opted for a hop-on, hop-off trolley bus this time. A bit of history from the driver but I didn’t really pay much attention to what she was saying. I was just enjoying having someone else doing the driving for the moment. Again, it was hot, so we ate lunch on River Street in a popular restaurant with good air conditioning.

| Photo Courtesy of Karen Bernath. (Just what was Karen doing in the men’s room?) |

Dinner was also down on River Street, at the Chart House. There are lots of other options, but we like the Chart House in Savannah and always seem to dine there. After dinner, we opted for drinks at the roof top bar of the Bohemian Hotel, quite a view of the river and the city. It was not overly crowded (good!) but still quite warm. We drank ‘cold’ things like ‘ice cream on the rocks’.

Day 9 of this Road Trip, 17 October 2018, was in St Augustine, FL. We stayed right in the heart of the historic district in a lovely old Bed and Breakfast hotel, the Southern Wind Inn. One of the supposedly ‘less’ haunted Inns in St Augustine. In the afternoon, well before dinner, while some folks went shopping, the rest of us found ourselves sitting on the second floor veranda, rocking in wicker chairs, drinking wine and watching the world go by. Glorious! Simply glorious! Karen and Chuck chose to head home as they live quite near in Jacksonville, FL (or was it that they knew for sure their house wasn’t haunted?)

Day 10 of this Road Trip, 18 October 2018 found us travelling home. Ron and Kathy left early to get back to Winter Park, FL to see a Rover mechanic. Ron had some gremlins he wanted to address before traveling back to the west coast of Florida. After breakfast, the Frazees, Stanleys and Braunsteins took off for central Florida together until we each peeled off in our various directions for home.

The end of another superb Morgan adventure! We all had mixed emotions about it ending. On one hand we were ready for the trip to end, we were tired, a bit ‘road weary’ and Andrea wanted to see her dogs. On the other hand, however, we simply wanted more. I saw a sign for Miami and briefly thought ‘let’s go’!

I guess we will have to plan something else soon!!

See More Pictures in the Photo Gallery. Click the link below

http://www.mogsouth.com/2018/10/22/gatormogs-2018-mid-atlantic-road-trip-2/

Well, we did it. Minimal drama. Lots of new roads and morning traffic, but Morgans traveling in groups is a good thing . . . I think. Makes us more visible to the ‘not quite awake’ folks suffering (sleeping?) through this same commute – day after day after day – more focused on the ‘day ahead’ than the rest of the world or too busy texting.

Well, we did it. Minimal drama. Lots of new roads and morning traffic, but Morgans traveling in groups is a good thing . . . I think. Makes us more visible to the ‘not quite awake’ folks suffering (sleeping?) through this same commute – day after day after day – more focused on the ‘day ahead’ than the rest of the world or too busy texting.